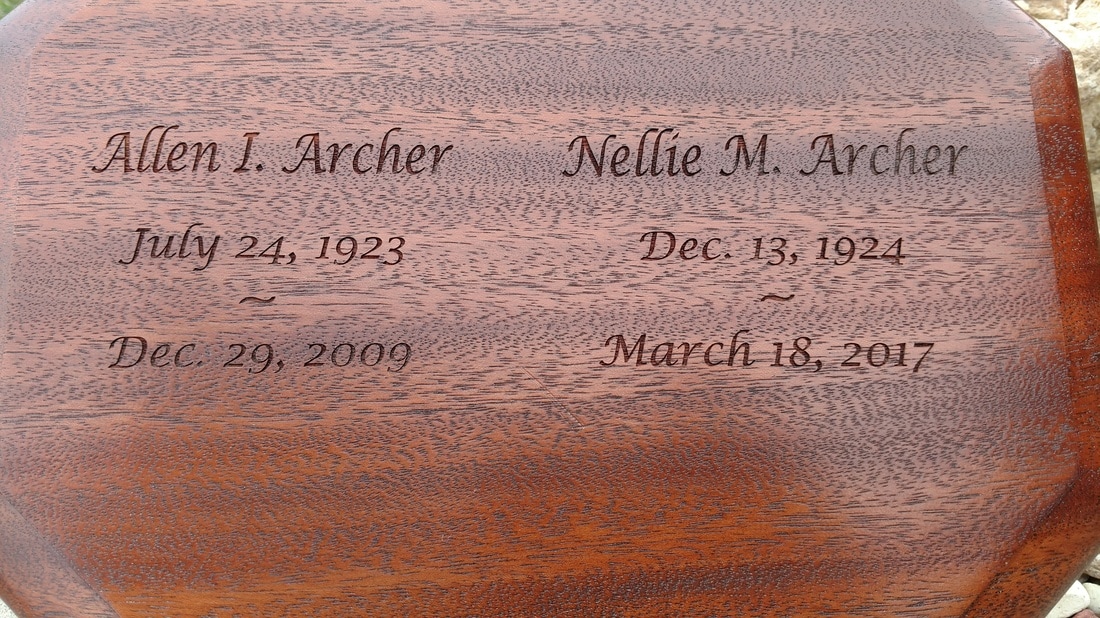

Size, and font are always a challenge to match exactly but overall on this job I think we did great work. Understanding the kind of wood you are dealing with along with any stain or finish that is applied is very important. Normally in a situation like this we will do a practice run on a scrap piece of wood to make sure the size and fonts will look as we are expecting. Because there is only one chance at something like this we take every precaution possible and double and triple check our measurements and spellings. Then once we are satisfied we will run it for real.

It feels good to match and create something as special as this for our customers.

RSS Feed

RSS Feed